Cranfield’s Space Research Centre is the principal focus for space engineering in the University although significant expertise in specific space technologies is distributed across all Schools. Cranfield SRC teaches the MSc in Astronautics and Space Engineering, from which alumni now work in almost all significant space organisations in the UK, Europe and globally.

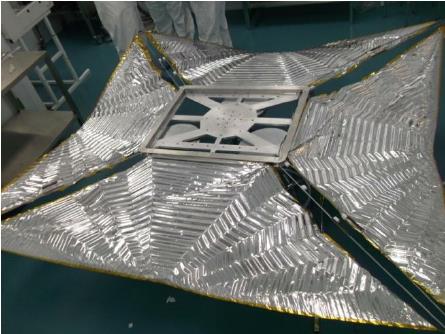

Cranfield is a world-leader in the development and supply of de-orbit drag sails for small LEO satellites. Two of these devices are currently in orbit and a third is ready for launch on ESA’s ESEO satellite. These programmes were managed by Cranfield staff, using development and assembly facilities on-site and with support for specialist test facilities from other UK organisations (Open University, RAL Space, and University of Southampton). This builds on more than a decade of research into space debris and its mitigation by a variety of techniques. The Cranfield devices ensure that the orbits of the spacecraft will decay within 25 years of their end of mission, to meet the current international guidelines. Using Cranfield’s devices has enabled the manufacturer to demonstrate compliance with these guidelines and thus to secure a launch licence. The figure below shows the UK’s TechDemoSat-1 (TDS-1) satellite which carries Cranfield’s Icarus de-orbit sail. TDS‐1 is based on an SSTL‐150 spacecraft bus (approx. 160 kg, 70 x 70 x 90 cm3).

Drag sail design and build

TDS-1’s mission runs until the de-orbit sail is deployed; the satellite’s orbit decay will then accelerate and re-entry is expected after about a decade (the precise date depends on solar activity and the satellite’s orientation).

TDS-1’s mission runs until the de-orbit sail is deployed; the satellite’s orbit decay will then accelerate and re-entry is expected after about a decade (the precise date depends on solar activity and the satellite’s orientation).

SRC Facilities

The Space Research Centre has a comprehensive range of support facilities including:

- Cleanroom (ISO 8, class 100,000): 4 m x 3 m x 4 m working volume designed for assembly and integration of small satellites (≤100 kg) and payloads (and adjacent cleanrooms capable of providing working volumes to ISO 5 / class 100).

- Satellite ground station: Capable of receiving and transmitting on the amateur radio VHF and UHF bands, for work with cubesats and other small satellites using these bands

- Airfield access: with National Flying Laboratory and Cranfield University aircraft

- Industry-standard engineering design tools: Satellite ToolKit, ESATAN, CATIA, NASTRAN/ PATRAN, I-DEAS

- Rapid-prototyping and instrumentation / electronics laboratory

- Hypersonic gun tunnel: for launch / re-entry simulation

Other Facilities for Space Research

Cranfield University has notable world-class facilities in some areas relevant to space engineering:

- Ultra-precision surface manufacturing and metrology: Cranfield has world-leading capabilities in ultra-precision engineering. Its facilities were recently used to manufacture and test optical surfaces for the James Webb space telescope

- Off-road vehicle testing facility (e.g. for planetary rover development and test)

- Bioscience laboratories supporting Space Biotechnology activities

- UAV (Unmanned Aerial Vehicle): extensive expertise in UAV / aerobot development and operations.

In addition to these there are other facilities which are of national importance:

- Ground-based radar for field experiments (Shrivenham)

- Autonomous vehicle outdoor instrumented roadway and test area

- Material science analytical tools

- Engineering photonics: optical measurement facilities

- Hyper / high velocity impact

- Space propulsion: a bi-propellant test rig is being developed for research and teaching, and will be operated in collaboration with the national centre of propulsion expertise at Westcott.